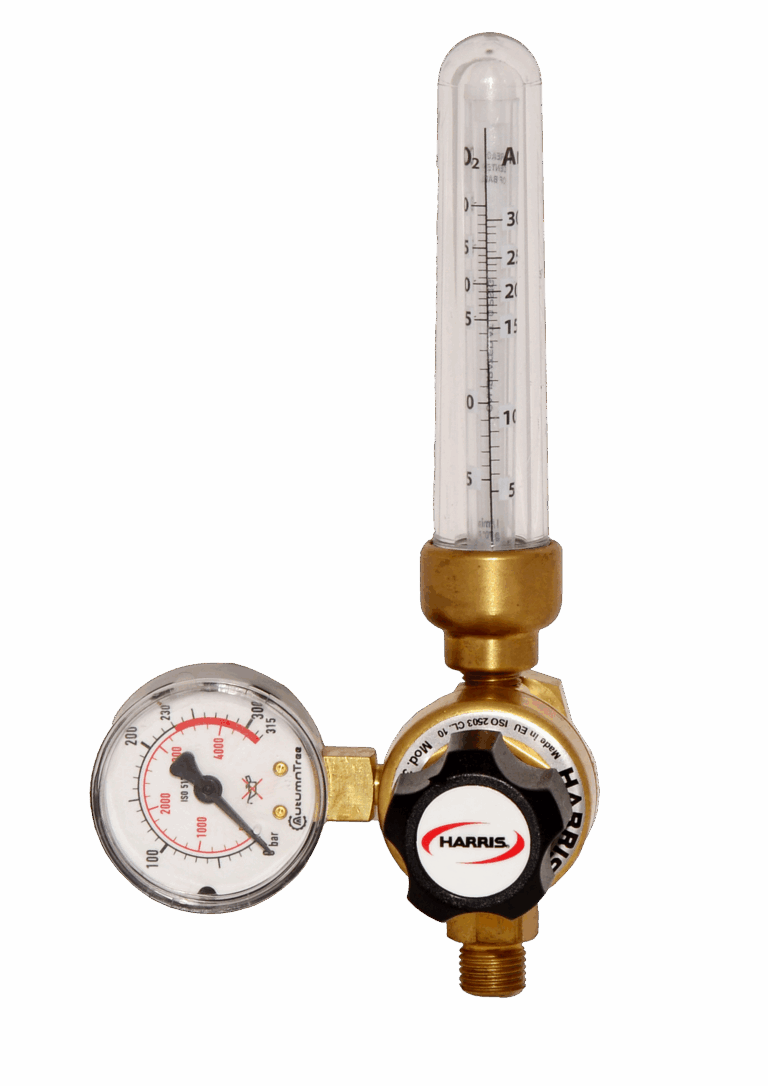

• Harris Inert Gas Guards are designed to save shielding gases in two ways:

- by reducing the gas surge when a MIG gun or TIG torch is activated. Because they are

designed to reduce the pressure held in supply hose, gas waste is reduced when the gun or

torch is triggered

- by delivering a controlled flow rate

• Operators will typically set shielding gas flow rates higher than necessary for a welding

operation. Once set by a supervisor, the Inert Gas Guard delivers the precise amount of flow for

the operation, eliminating the needless waste of gas.